Precision You Can Rely On

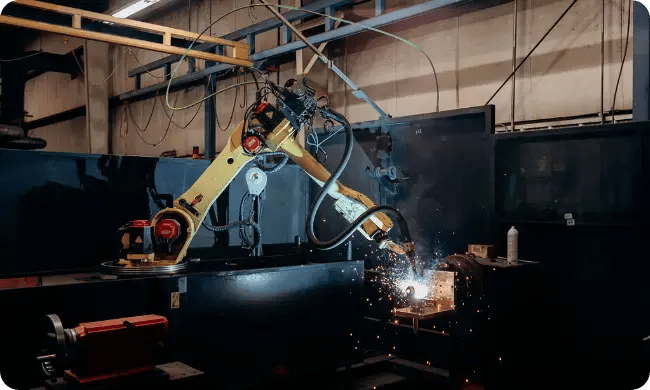

HIGH-STRENGTH FABRICATION YOU CAN TRUST

At CIGNYS, we provide precision fabrication built for industries that demand strength, accuracy, and long-term performance.

100+ YEARS OF PERFORMANCE

FABRICATION THAT EXCEEDS STANDARDS

For over a century, CIGNYS has been a leader in precision fabrication, innovation, and manufacturing excellence. Our state-of-the-art facility is equipped with robotic welding work cells, multiple water jet tables, advanced plasma and water jet cutting technologies, and AWS-qualified welding procedures and certified welders to ensure unmatched strength, accuracy, and durability.

Whether you're in aerospace, defense, automotive, or industrial manufacturing, our fabrication solutions are built to withstand demanding environments while meeting the highest industry standards.

ENGINEERED FOR STRENGTH, BUILT FOR RELIABILITY.

HIGH-QUALITY FABRICATION, START TO FINISH

Select an option below:

- CUTTING

- PRECISION WELDING

- STRUCTURAL FABRICATION

- FINISHING & ASSEMBLY

Precision Cutting & Forming for Complex Fabrication

Getting the perfect cut is about more than just shaping metal, it’s about accuracy, efficiency, and repeatability. At CIGNYS, we utilize advanced water jet-cutting technologies to achieve precise tolerances, clean edges, and optimal material utilization.

Whether working with steel, aluminum, or specialty alloys, our cutting and forming capabilities ensure your components meet your exact specifications, every time.

Strong, Reliable Welds for Demanding Applications

In industries where precision and strength are critical, welding quality can’t be left to chance. CIGNYS’ AWS-qualified welding procedures, including robotic, semiautomatic, and manual welding, ensure high-strength bonds, repeatable accuracy, and long-lasting durability for even the most complex fabrications.

Our team is skilled in working with steel, aluminum, stainless, and specialty alloys, delivering welded components that perform under extreme conditions.

High-Strength Fabrication for Complex Structures

From heavy-duty frameworks to intricate assemblies, CIGNYS’ structural fabrication services ensure strength, accuracy, and long-term durability. Our team specializes in complex metal fabrications, utilizing robotic welding, advanced forming, and cutting technologies to meet the highest industry standards.

Whether it’s for defense, aerospace, automotive, or industrial applications, we build components that stand up to extreme conditions and demanding requirements.

The Finishing Touch for Performance and Protection

A product is only as strong as its final finish and assembly. At CIGNYS, we offer comprehensive finishing and assembly solutions, ensuring every component is protected, precision-assembled, and built to perform.

Our capabilities include CARC painting, surface treatments, and manual or semi-automated assembly processes, delivering turnkey solutions that meet industry standards for durability and reliability.

Delivering Components You Can Trust Every Time

Quality issues can cost time, money, and your reputation. That’s why CIGNYS follows rigorous quality control procedures to ensure that every component meets your exact specifications.

Our AS 9100D, ISO 9001:2015, and ITAR-compliant processes include first-article inspections, in-process monitoring, and final verification using CMM (Coordinate Measuring Machines), laser scanning, and precision metrology tools. With consistent quality assurance at every stage, you can trust that your parts will perform reliably in even the most demanding applications.

BUILT STRONG, FABRICATED RIGHT

CUTTING-EDGE FABRICATION

At CIGNYS, we don’t just fabricate—we engineer smarter solutions using advanced technology for stronger, more precise, and cost-effective components. From robotic welding for unmatched consistency to high-precision cutting that reduces waste, our innovations help you streamline production, improve part performance, and meet the strictest industry standards.

- Automated Welding & Cutting – Ensures repeatability and precision for high-strength components.

- Efficient Material Processing – Optimized water jet cutting minimizes waste.

- Scalable Production Capabilities – From prototyping to high-volume production, we meet your needs.

NEED HELP? START WITH OUR MOST ASKED QUESTIONS

-

What types of materials can CIGNYS fabricate?

CIGNYS works with steel, aluminum, stainless steel, and specialty alloys, using advanced cutting, forming, and welding techniques to meet exact specifications.

-

Do you provide custom fabrication solutions?

Yes! Our team specializes in custom metal fabrication, whether you need low-volume or full-scale production runs.

-

What welding processes does CIGNYS use?

We offer AWS-certified robotic and manual welding, ensuring precision, strength, and repeatability for even the most complex fabrications.

-

Can CIGNYS reverse-engineer and fabricate replacement parts?

Absolutely. We can reverse-engineer obsolete or hard-to-source parts, fabricating components that match or exceed OEM specifications.

-

How long does fabrication typically take?

Lead times depend on project complexity and volume, but we prioritize efficient production workflows to deliver high-quality parts on time.

-

How does CIGNYS ensure fabrication quality?

We use AWS-certified welding, precision machining, and rigorous quality control processes to ensure every fabricated component meets exact specifications.

WHY PARTNER WITH CIGNYS

EXPERTISE YOU CAN TRUST. RESULTS YOU CAN RELY ON.

High Quality Parts |

|

Our components are designed and manufactured with precision and inspected to meet the most rigorous defense and aerospace standards. Trust us to deliver reliability where it matters most.

Fast Lead Time |

|

We know time is critical in the defense industry. Our program management and commitment, along with streamlined processes and advanced technology ensure your parts are delivered on time, without compromising quality.

Engineering Support |

|

From design to validation, our team works with you every step of the way. With expertise in prototyping, design for manufacturability, and production, we help bring your vision to life efficiently and effectively.

PROUD PARTNERS IN EXCELLENCE

CONTACT US TODAY

LET’S TALK ABOUT YOUR NEXT FABRICATION PROJECT

Facing a fabrication challenge? CIGNYS provides durable, high-performance fabrication solutions tailored to your exact needs. Let’s discuss your project.