PROTECT. STRENGTHEN. PERFORM.

PRECISION PAINTING FOR MAXIMUM DURABILITY

CIGNYS' precision painting services, including NACE certified painters and CARC capabilities, ensure that your components are protected, long-lasting, and meet strict industry requirements.

DECADES OF EXPERIENCE

PAINTING THAT PROTECTS AND PERFORMS

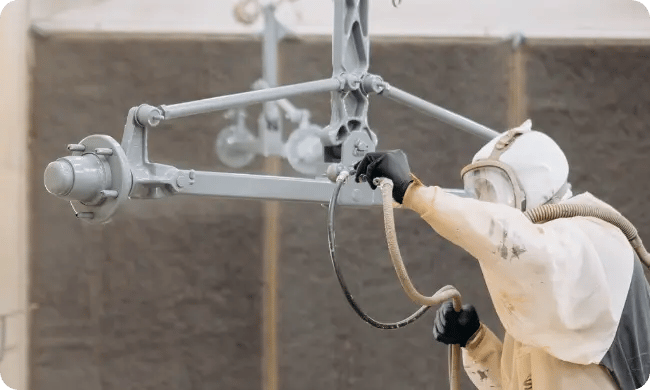

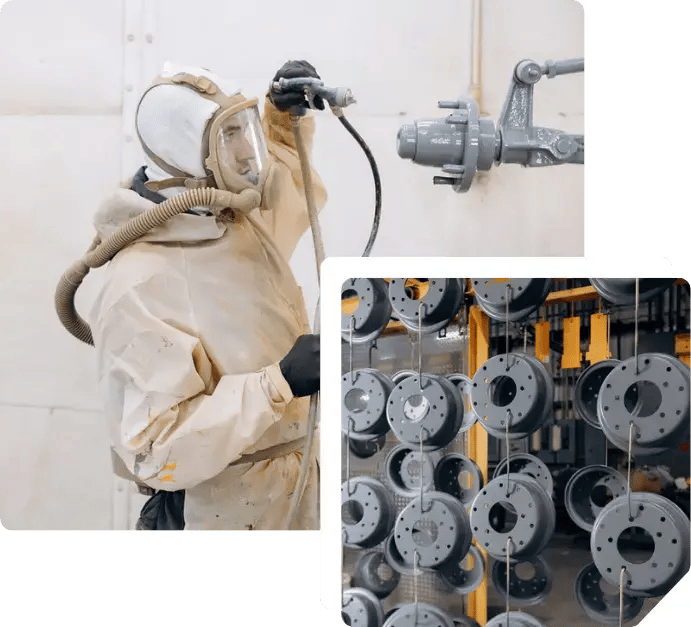

At CIGNYS, we know that a high-quality finish is more than just paint—it’s protection, durability, and performance. Our STAR4D certified painters and blast technicians, paired with our AMPP Coatings and Corrosion Certified Technician on Staff, CARC-certified painting processes, advanced paint booths, and high-capacity monorail systems ensure every component meets the toughest industry standards for defense, aerospace, and industrial applications.

We ensure that every painted component meets strict performance and durability requirements. Whether for corrosion resistance, chemical protection, or military-grade coatings, our precision painting process guarantees long-lasting results you can trust.

PRECISION COATINGS FOR MAXIMUM PROTECTION.

COMPREHENSIVE PAINTING SOLUTIONS

Select an option below:

- PROTECTIVE COATINGS

- CARC PAINTING

- QUALITY CONTROLLED FINISHING

Protective Painting That Goes Beyond the Surface

A great finish does more than enhance appearance, it provides long-lasting protection against corrosion, wear, and environmental damage. At CIGNYS, our precision-applied protective coatings are designed for aerospace, defense, and industrial applications, ensuring strength, durability, and compliance with industry standards.

We also offer custom color matching and specialty finishes, allowing your components to meet specific branding, military specifications, or industrial requirements. Whether you need a matte, gloss, or textured finish, our coatings provide both visual consistency and long-term durability.

CARC Painting for Military-Grade Protection

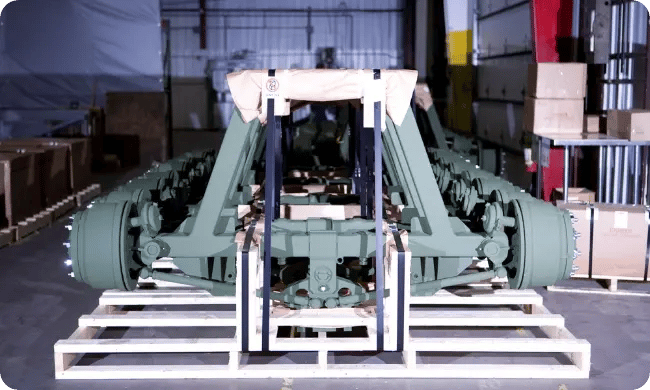

For defense and military applications, a standard paint job isn’t enough. CIGNYS uses Chemical Agent Resistant Coatings (CARC) that provide exceptional durability, chemical resistance, and battlefield protection.

Our CARC-certified paint processes ensure long-lasting performance, corrosion resistance, and compliance with strict military specifications. With precision application and quality control, we deliver mission-ready coatings built to be able to withstand the harshest environments.

Quality Ensured Industrial Painting Solutions

At CIGNYS, we adhere to strict quality control processes, ensuring every coated component meets aerospace, defense, and industrial standards.

Our finishing processes are conducted under AS 9100D, ISO 9001, and ITAR-compliant quality management systems, guaranteeing precision application, thorough inspection, and adherence to customer specifications. Whether it’s a military-grade protective coating or a high-performance industrial finish, we ensure your parts meet exact requirements.

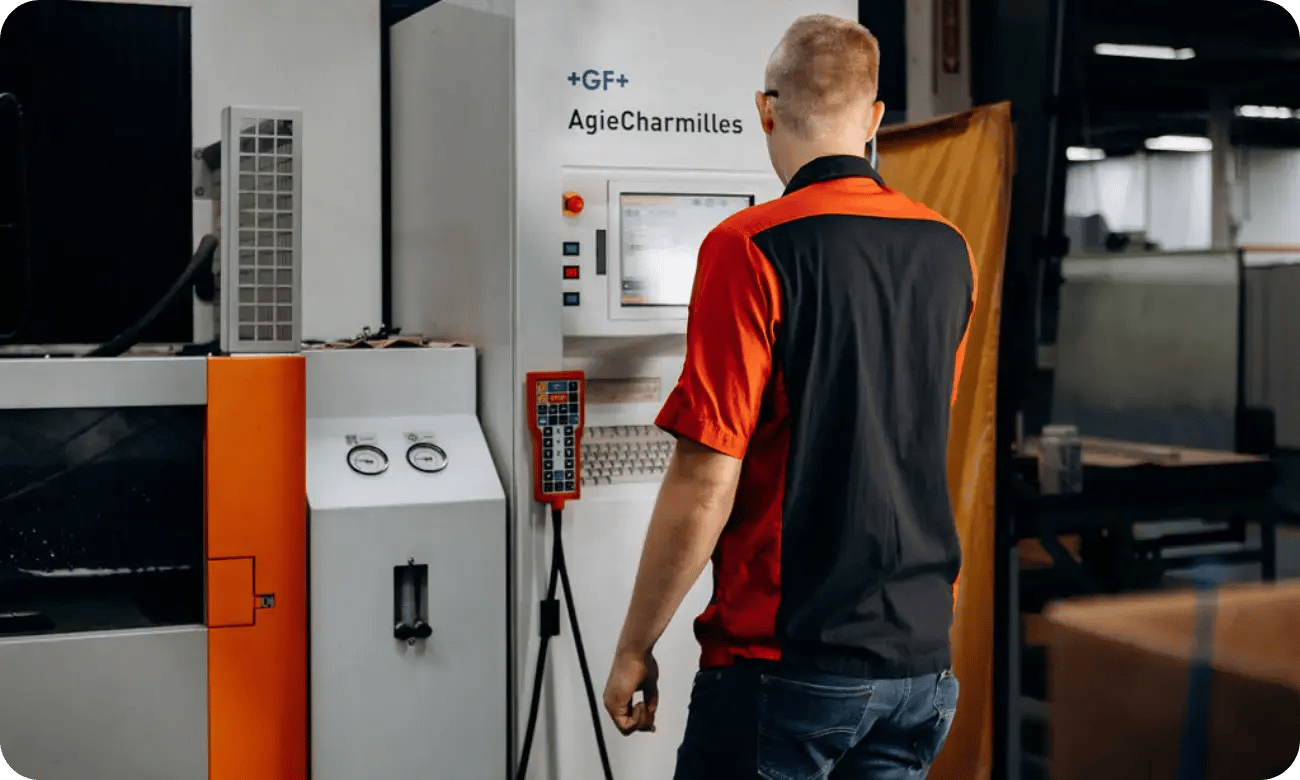

Manufacturing High-Precision Components and Parts

When off-the-shelf solutions don’t meet your requirements, CIGNYS provides precision machining and engineering services to create custom, high-performance components tailored to your exact specifications. Our 5-axis machining, multi-axis turning centers, and automated production systems ensure every part is built with repeatable accuracy and superior quality.

Whether you need low-volume specialty parts or high-volume production, our expertise in precision engineering helps you reduce downtime, improve efficiency, and guarantee reliable performance.

Delivering Components You Can Trust Every Time

Quality issues can cost time, money, and your reputation. That’s why CIGNYS follows rigorous quality control procedures to ensure that every component meets your exact specifications.

Our AS 9100D, ISO 9001:2015, and ITAR-compliant processes include first-article inspections, in-process monitoring, and final verification using CMM (Coordinate Measuring Machines), laser scanning, and precision metrology tools. With consistent quality assurance at every stage, you can trust that your parts will perform reliably in even the most demanding applications.

CUTTING-EDGE PAINTING SOLUTIONS

CLEANING AND PAINTING EQUIPMENT

At CIGNYS, we combine expert craftsmanship with advanced painting technology to ensure high-quality, consistent finishes on every component. Our painting facilities are equipped with pre-painting cleaning equipment and large-capacity paint booths and monorail conveyor systems, allowing us to efficiently coat everything from small parts to large, complex components.

- Shot Blast Booth - Manual, 14' wide x 40' long x 10' high

- Large Paint Booth – 20’ wide x 48’ long with a 4-ton hoist for handling oversized components.

- Manual Paint Booth – Equipped with 32 hooks for controlled, high-precision applications.

- Monorail Paint Conveyors – Includes a Heavy-Duty Line with 400 hooks (200 lb. capacity each) and a Light-Duty Line with 60 hooks (65 lb. capacity each).

- Equipment - Agitated 2.8-gallon Binks paint pots, DeVilbiss HVLP paint guns, GOFF blast machine, TRINCO blast cabinets

NEED HELP? START WITH OUR MOST ASKED QUESTIONS

-

What types of painting solutions does CIGNYS offer?

CIGNYS provides precision industrial painting, including protective coatings, CARC painting, and high-durability industrial finishes for aerospace, defense, and industrial applications.

-

Does CIGNYS offer CARC paint solutions?

Yes! We offer Chemical Agent Resistant Coatings (CARC), a specialized finish designed for military and defense applications. CARC paint provides chemical resistance, durability, and protection in extreme environments.

-

What industries do you serve with your painting solutions?

We provide high-performance coatings for defense, aerospace, industrial, and automotive applications, ensuring we meet compliance with strict industry standards.

-

Can CIGNYS match specific colors or finishes?

Yes! We offer custom color matching and specialty finishes, including matte, gloss, and textured coatings, tailored to your exact specifications.

-

How long does the painting process take?

The timeline for each project depends on size, complexity, and coating type. We work efficiently to meet your deadlines without compromising the quality or durability of the finish.

-

Can CIGNYS handle large or high-volume painting projects?

Yes! Our monorail paint conveyor system allows us to efficiently coat high volumes of components, including large or complex parts.

WHY PARTNER WITH CIGNYS

EXPERTISE YOU CAN TRUST. RESULTS YOU CAN RELY ON.

High Quality Products |

|

Our components are designed and manufactured with precision and inspected to meet the most rigorous defense and aerospace standards. Trust us to deliver reliability where it matters most.

Fast Lead Time |

|

We know time is critical in the defense industry. Our program management and commitment, along with streamlined processes and advanced technology ensure your parts are delivered on time, without compromising quality.

Engineering Support |

|

From design to validation, our team works with you every step of the way. With expertise in prototyping, design for manufacturability, and production, we help bring your vision to life efficiently and effectively.

PROUD PARTNERS IN EXCELLENCE

HAVE A PROJECT IN MIND?

CONTACT US TO DISCUSS YOUR PAINTING NEEDS

Need help with a painting project? CIGNYS offers precision-paint solutions tailored to your needs. Contact us for a free consultation.