DESIGNS THAT WORK. SOLUTIONS THAT LAST

ENGINEERING & DESIGN FOR COMPLEX CHALLENGES

At CIGNYS, we deliver innovative engineering and design services tailored to meet the most demanding requirements. Our team is highly skilled in design for manufacturability. Whether it’s reverse engineering, prototyping, or full-scale production, we bring your ideas to life with precision and reliability.

INNOVATING SINCE 1919

TRUSTED ENGINEERING AND DESIGN SERVICES

CIGNYS is proud to deliver engineering and design services prioritizing precision, innovation, and reliability. As an AS 9100D, ISO 9001:2015, and ITAR-registered organization, we provide advanced manufacturing solutions for industries like aerospace, defense, and more. From reverse engineering to cutting-edge machining, our services are designed to meet your exact specifications while supporting American craftsmanship and quality.

DESIGN SMARTER. ENGINEER BETTER. BUILD STRONGER.

HIGH-PERFORMANCE MANUFACTURING SOLUTIONS

Select an option below:

- DESIGN

- VALIDATION

- PROTOTYPING

- MACHINING

- QUALITY CONTROL

Design for Manufacturability (DFM)

CIGNYS thrives on collaboration with our customers. Clear communication and follow-through are the foundation of a reliable and trustworthy partnership, and what we pride ourselves on. Early involvement in the design cycle allows our cross-functional team to provide know-how on how to reduce manufacturing costs, improve quality and reliability, minimize rework and scrap, and accelerate time to market. Count on us to ensure that your designed parts are manufacturable and that mating components fit together correctly the first time.

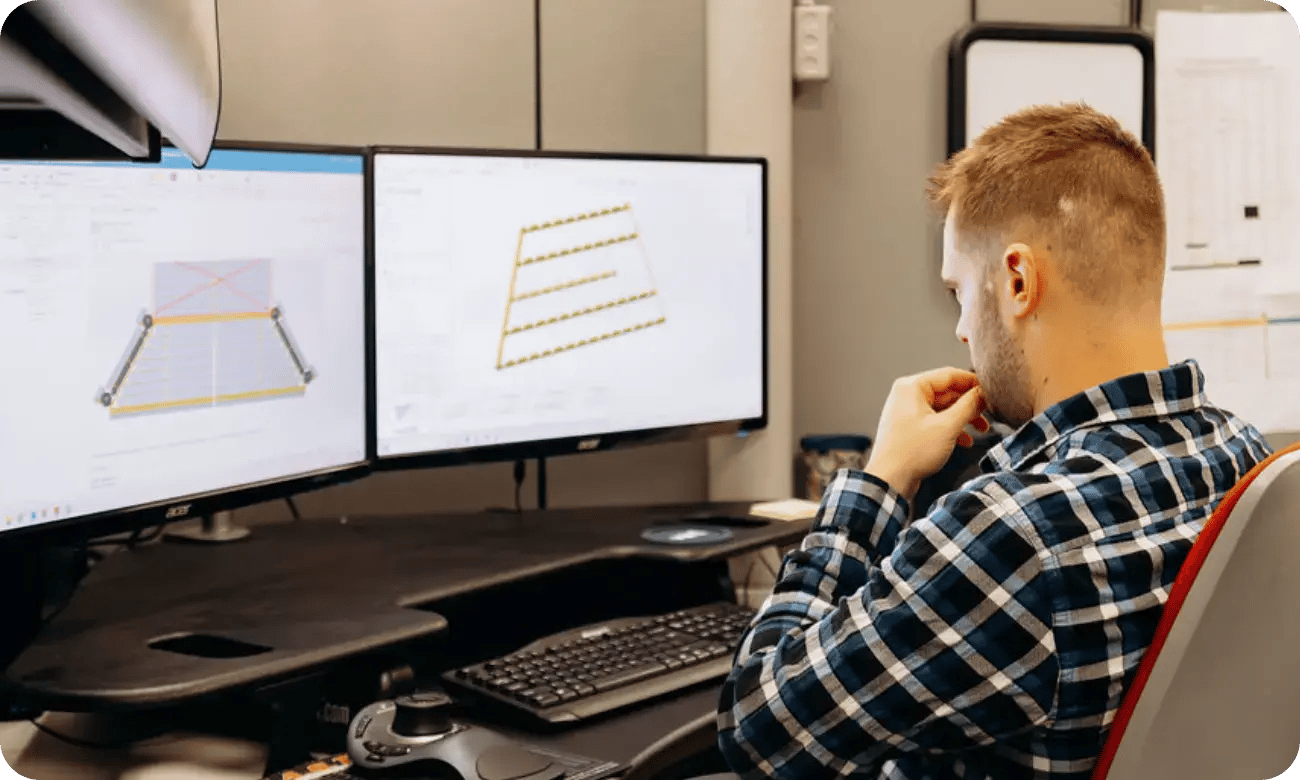

Turning Your Vision Into a Manufacturable Solution

Many companies struggle with translating concepts into production-ready designs. At CIGNYS, our engineering and design experts work with you to refine your designs, ensuring they are optimized for performance, durability, and cost-efficiency while meeting the most stringent requirements. Using advanced CAD modeling and industry-leading software, we create detailed blueprints that eliminate manufacturability issues early on.

By leveraging our expertise in material selection, structural integrity, design for manufacturability, and precision engineering, we help you avoid costly design flaws and bring your product to life with accuracy and confidence.

Ensuring Your Design Meets Real-World Demands

A design is only as good as its ability to perform under real-world conditions. At CIGNYS, we provide comprehensive validation services, using Finite Element Analysis (FEA), stress testing, and digital simulations to verify strength, durability, and compliance with industry regulations.

Our validation process ensures that your components perform reliably before they ever reach production, eliminating unexpected failures and costly revisions. By refining your design early, we help you reduce waste, lower costs, and accelerate time to market.

Testing Before You Commit to Full Production

Uncertainty in the manufacturing process can lead to wasted time and resources. At CIGNYS, our prototyping services provide a risk-free way to test and refine your components before full-scale production.

Whether you need a single prototype for testing or small-batch production for pilot runs, we deliver high-precision prototypes using CNC machining, 3D printing, and fabrication techniques. This allows you to identify improvements, test fit and function, and make adjustments before investing in full production—ensuring cost savings and optimal product performance.

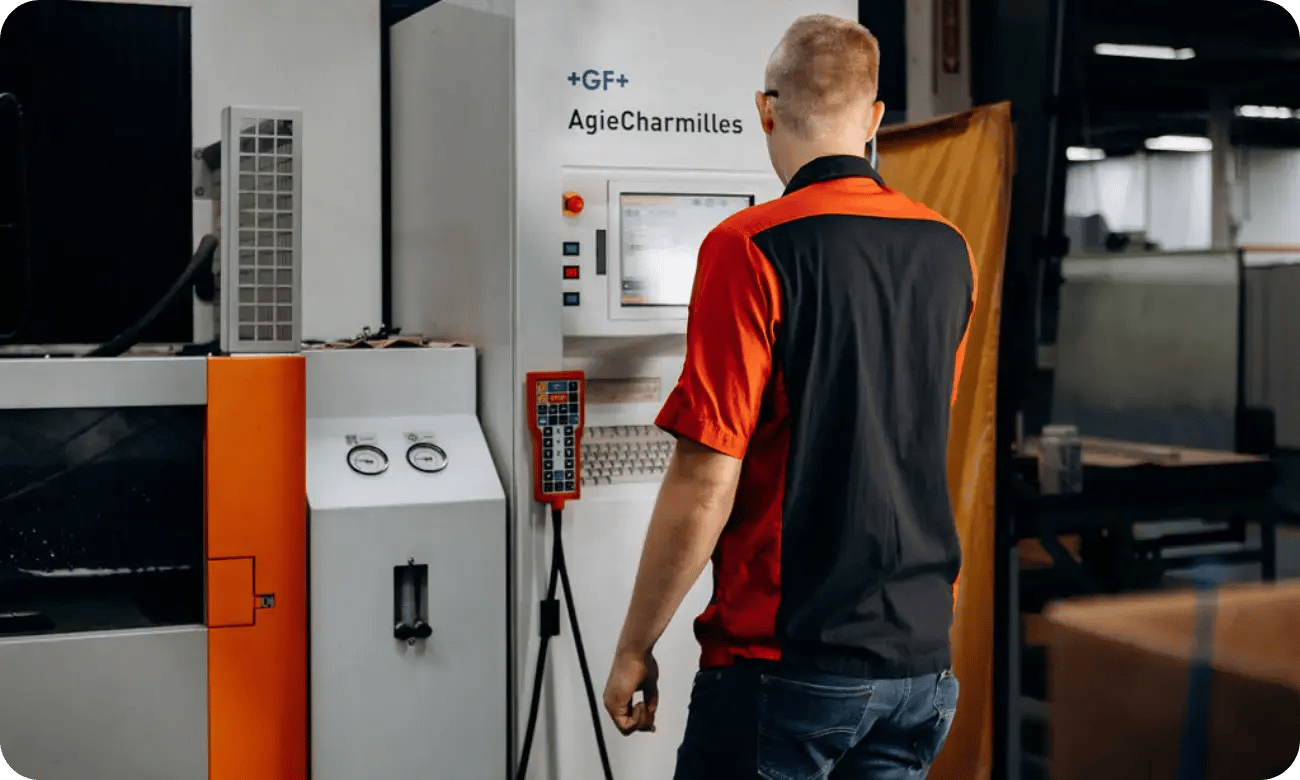

Manufacturing High-Precision Components and Parts

When off-the-shelf solutions don’t meet your requirements, CIGNYS provides precision machining and engineering services to create custom, high-performance components tailored to your exact specifications. Our 5-axis machining, multi-axis turning centers, and automated production systems ensure every part is built with repeatable accuracy and superior quality.

Whether you need low-volume specialty parts or high-volume production, our expertise in precision engineering helps you reduce downtime, improve efficiency, and guarantee reliable performance.

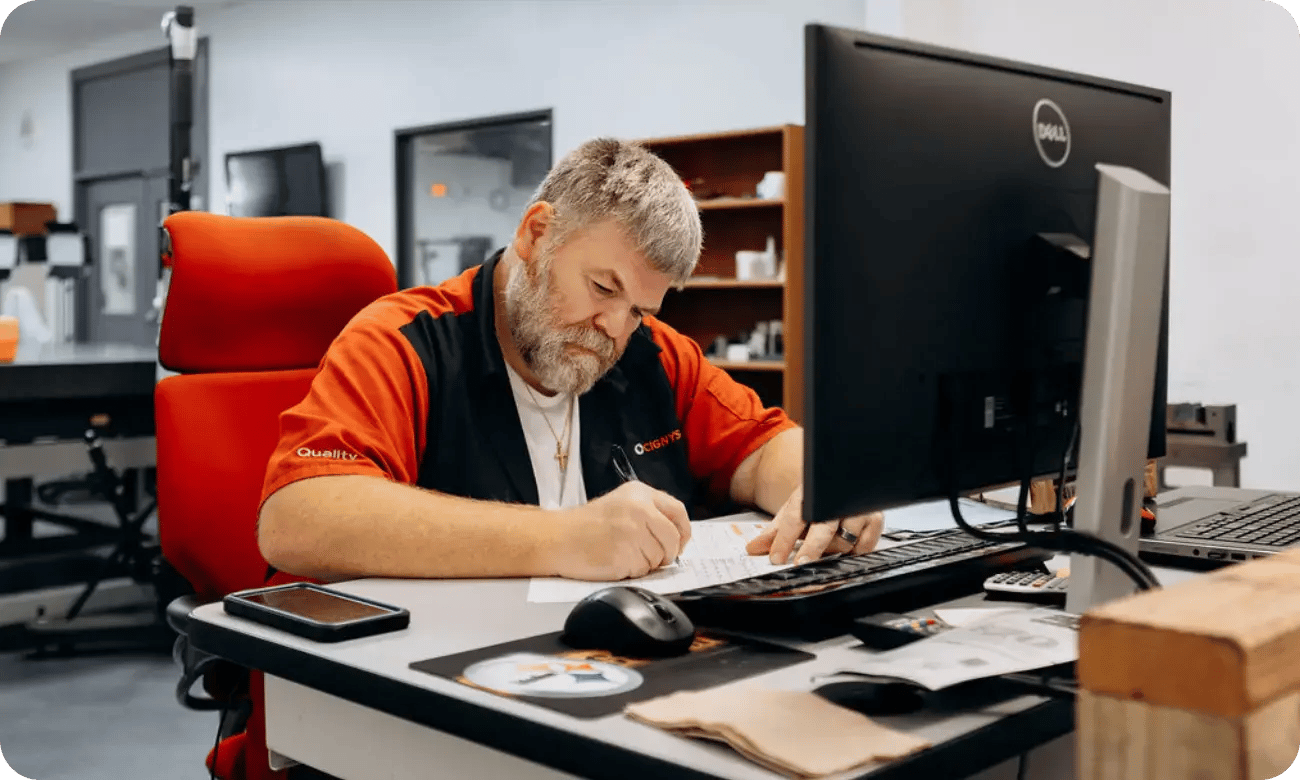

Delivering Components You Can Trust Every Time

Quality issues can cost time, money, and your reputation. That’s why CIGNYS follows rigorous quality control procedures to ensure that every component meets your exact specifications.

Our AS 9100D, ISO 9001:2015, and ITAR-compliant processes include first-article inspections, in-process monitoring, and final verification using CMM (Coordinate Measuring Machines), laser scanning, and precision metrology tools. With consistent quality assurance at every stage, you can trust that your parts will perform reliably in even the most demanding applications.

FOR OBSOLETE COMPONENTS

REVERSE ENGINEERING

When OEM parts become obsolete, lead times are too long, or modifications for improvement are needed, CIGNYS' reverse engineering solutions provide an efficient and cost-effective alternative. Using state-of-the-art metrology, advanced CAD modeling, and material analysis, we recreate mission-critical components with precision and performance that meet or exceed original specifications.

- 3D Scanning & Precision Measurement – Capturing exact dimensions with high-accuracy metrology tools.

- Material Identification & Analysis – Ensuring components match strength, durability, and performance requirements.

- CAD Modeling & Digital Reconstruction – Developing detailed, production-ready designs for seamless manufacturing.

- Manufacturing & Testing – Producing parts with tight tolerances and verifying performance through rigorous quality control.

NEED HELP? START WITH OUR MOST ASKED QUESTIONS

-

Can you work from my existing designs, sketches, or blueprints?

Yes, we can! We have the ability to work from CAD files, sketches, blueprints or an idea.

-

What materials can you work with for engineering projects?

Anything metal!

-

Can CIGNYS replace components that are no longer available from the OEM?

Yes, CIGNYS specializes in reverse engineering components that are no longer available from OEMs or for equipment from manufacturers that are out of business. We analyze and recreate parts using state-of-the-art metrology and material identification to ensure interchangeability and reliability.

-

How quickly can CIGNYS deliver parts?

Our streamlined processes and advanced technology allow us to deliver parts with industry-leading turnaround times. Specific lead times depend on the complexity of the project, but we prioritize speed without compromising quality.

-

Do you provide post-production support or modifications?

Yes, we offer support after production, including modifications, repairs, and enhancements, to ensure your components continue to perform as needed.

-

Can CIGNYS design something for us?

Yes, CIGNYS offers custom engineering and design services to create tailored solutions for your specific needs. Our team works closely with you to develop innovative, high-quality designs that meet your requirements and exceed expectations.

WHY PARTNER WITH CIGNYS

EXPERTISE YOU CAN TRUST. RESULTS YOU CAN RELY ON.

High Quality Parts |

|

Our components are designed and manufactured with precision and inspected to meet the most rigorous defense and aerospace standards. Trust us to deliver reliability where it matters most.

Fast Lead Time |

|

We know time is critical in the defense industry. Our program management and commitment, along with streamlined processes and advanced technology ensure your parts are delivered on time, without compromising quality.

Engineering Support |

|

From design to validation, our team works with you every step of the way. With expertise in prototyping, design for manufacturability, and production, we help bring your vision to life efficiently and effectively.

PROUD PARTNERS IN EXCELLENCE

HAVE A PROJECT IN MIND?

CONTACT US TO DISCUSS YOUR ENGINEERING AND DESIGN NEEDS

Facing an engineering challenge? CIGNYS offers precision-engineered solutions tailored to your needs. Contact us for a free consultation.