OPTIMIZE YOUR OPERATIONS

HIGH-PRECISION MACHINING SOLUTIONS

Partner with CIGNYS to streamline production, reduce downtime, and achieve unmatched precision in every part, on time and on quality.

BACKED BY DECADES OF EXPERTISE

HIGH-QUALITY MACHINING AND PERFORMANCE

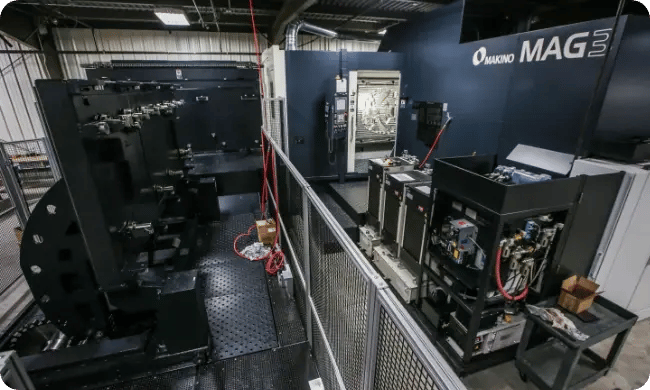

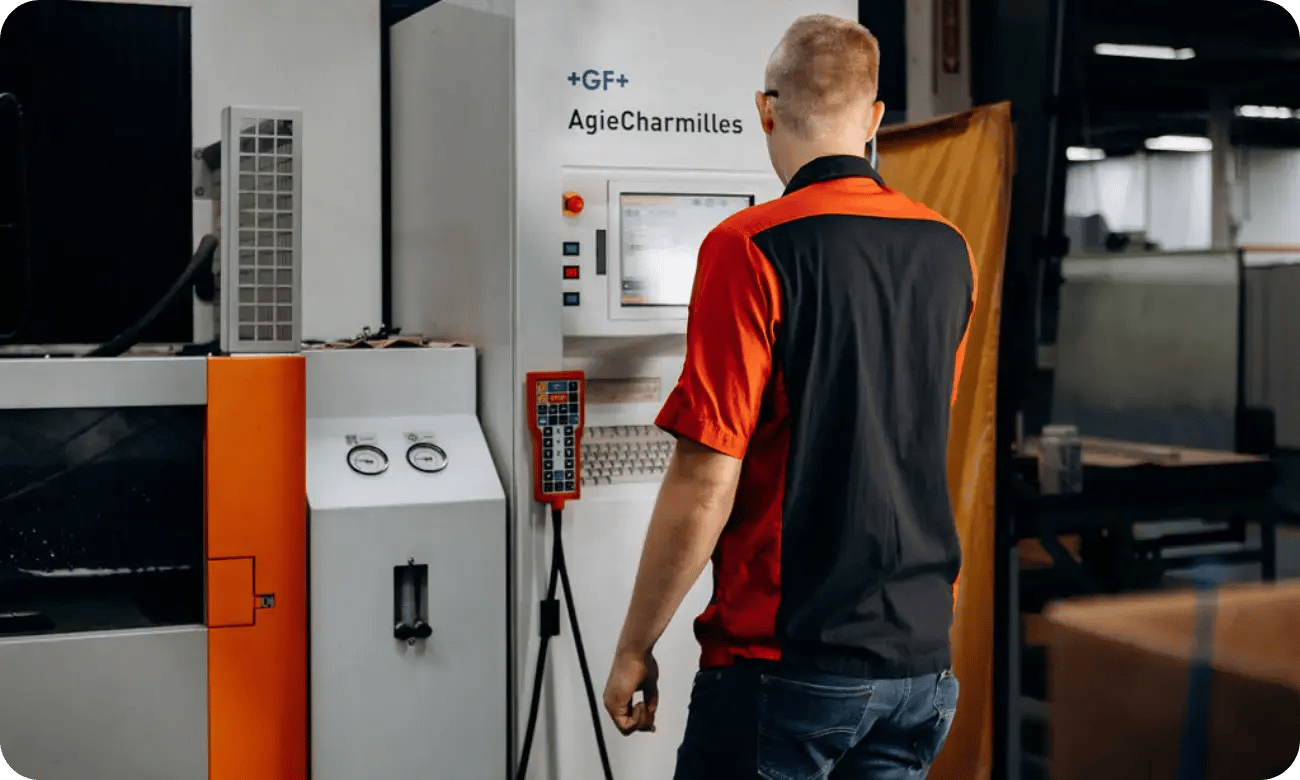

For over a century, CIGNYS has been at the forefront of precision machining, innovation, and manufacturing excellence. Our state-of-the-art facility is equipped with the latest CNC mills, multi-axis machining centers, and automated pallet systems to ensure tight tolerances, repeatable accuracy, and cost-efficient production.

Whether you're in aerospace, defense, automotive, or industrial manufacturing, our machining solutions are engineered to meet the highest industry standards and perform in the most demanding applications.

ENGINEERED FOR ACCURACY, BUILT FOR PERFORMANCE

COMPLETE PRECISION MACHINING SOLUTIONS

Select an option below:

- CNC MILLING & TURNING

- MULTI-AXIS MACHINING

- MATERIAL CAPABILITIES

- QUALITY CONTROL & FINISHING

- PRODUCTION MACHINING

Low, Mid, and High-Volume Production

CIGNYS specializes in high-precision production machining, delivering consistent quality and efficiency across low, mid, and high-volume production runs. Our automated machining centers, palletized systems, and multi-axis CNC machines ensure repeatability, cost-effectiveness, and reduced lead times.

Whether you're producing a small batch of critical components or ramping up to full-scale manufacturing, our state-of-the-art machining technology guarantees precision at every stage.

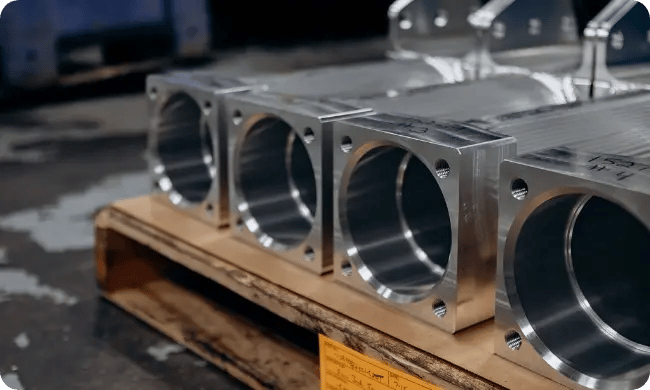

Precision Machining for Complex Components

CIGNYS specializes in high-precision CNC milling and turning, delivering tight-tolerance components for aerospace, defense, industrial, and automotive applications.

Our multi-axis machining centers and automated systems ensure repeatable accuracy, faster production times, and cost-efficient solutions for even the most complex geometries.

Multi-Axis Machining for Complex Geometries

With 5-axis and multi-axis CNC machining, CIGNYS produces high-precision parts with fewer setups and greater efficiency.

Our advanced technology allows for intricate part features, improved consistency, and enhanced durability, ensuring that every component meets exact specifications and performance demands.

Quality Materials Your Industry Can Rely On

The right material selection is critical to performance, longevity, and cost efficiency. CIGNYS has extensive experience machining a variety of metals.

Our expertise in material-specific machining techniques ensures that each part meets strength, weight, and durability requirements, giving you components that perform flawlessly under extreme conditions.

Manufacturing High-Precision Components and Parts

When off-the-shelf solutions don’t meet your requirements, CIGNYS provides precision machining and engineering services to create custom, high-performance components tailored to your exact specifications. Our 5-axis machining, multi-axis turning centers, and automated production systems ensure every part is built with repeatable accuracy and superior quality.

Whether you need low-volume specialty parts or high-volume production, our expertise in precision engineering helps you reduce downtime, improve efficiency, and guarantee reliable performance.

Delivering Components You Can Trust Every Time

Our high-precision machining processes adhere to AS 9100D, ISO 9001:2015, and ITAR-certified standards, ensuring full industry compliance. With in-process inspections, CMM verification, and laser scanning, we guarantee precision, consistency, and accuracy across every production run.

To provide a complete solution, we also offer painting and assembly services.

ADVANCED CAPABILITIES

STATE-OF-THE-ART MACHINING

Our investment in cutting-edge machining technology means higher efficiency, improved accuracy, and reduced costs for your project. By leveraging automation, high-speed machining, and advanced inspection techniques, CIGNYS delivers parts that meet exact specifications while optimizing lead times and production costs.

- 5-Axis & Multi-Axis Machining – Delivers greater flexibility, reduces setups, and allows for machining of complex shapes.

- High-Speed CNC Milling & Turning – Rapid production with repeatable accuracy, ensuring efficiency in both prototype and production runs.

- Precision Tolerance Control – Ensures consistent, tight tolerances, improving performance and longevity in mission-critical applications.

- Automated Pallet Handling Systems – Enhances production speed and efficiency, allowing for quick changeovers and minimal downtime.

- Advanced Quality Assurance – CMMs, laser scanning, and in-process inspections to guarantee parts meet exact specifications.

NEED HELP? START WITH OUR MOST ASKED QUESTIONS

-

What types of machining services does CIGNYS offer?

CIGNYS provides a comprehensive range of machining services, including CNC milling, turning, multi-axis machining, and precision grinding. Our capabilities encompass simple 2-axis turning to complex 5-axis milling, utilizing the latest tool technology and cutting techniques.

-

What materials can CIGNYS machine?

While specific materials are not detailed on our website, CIGNYS's advanced machining capabilities suggest proficiency with a range of materials, including various metals and plastics. For precise information regarding your specific material requirements, please contact us.

-

What industries does CIGNYS serve with its machining capabilities?

CIGNYS serves multiple industries, including defense, aerospace, industrial, and automotive sectors. Our high-end design, engineering, machining, and fabricating services are tailored to meet the specific needs of these industries.

-

What equipment does CIGNYS utilize for machining?

Our facilities are equipped with advanced machinery, including 29 CNC lathes (many with live tooling and bar feeders), 42 CNC mills with horizontal and vertical work envelopes, and 2 boring mills.

-

Does CIGNYS offer design and engineering support?

Yes, our design and engineering department utilizes advanced software, including AutoCAD, CATIA, Pro/Engineer, SolidWorks, and MasterCAM, allowing us to work from nearly any data file to meet your specific needs.

-

Can CIGNYS assist with reverse engineering projects?

Absolutely. CIGNYS has the capability to reverse engineer, customize, or provide new designs to meet specific requirements, especially when original components are no longer available from the OEM.

WHY PARTNER WITH CIGNYS

EXPERTISE YOU CAN TRUST. RESULTS YOU CAN RELY ON.

High Quality Products |

|

Our components are designed and manufactured with precision and inspected to meet the most rigorous defense and aerospace standards. Trust us to deliver reliability where it matters most.

Fast Lead Time |

|

We know time is critical in the defense industry. Our program management and commitment, along with streamlined processes and advanced technology ensure your parts are delivered on time, without compromising quality.

Engineering Support |

|

From design to validation, our team works with you every step of the way. With expertise in prototyping, design for manufacturability, and production, we help bring your vision to life efficiently and effectively.

PROUD PARTNERS IN EXCELLENCE

CONTACT US TODAY

READY FOR HIGH-PRECISION MACHINING SOLUTIONS?

At CIGNYS, we use cutting-edge technology, advanced machining, and strict quality control to deliver precision components. Let’s discuss how we can ensure accuracy, performance, and reliability in every part.